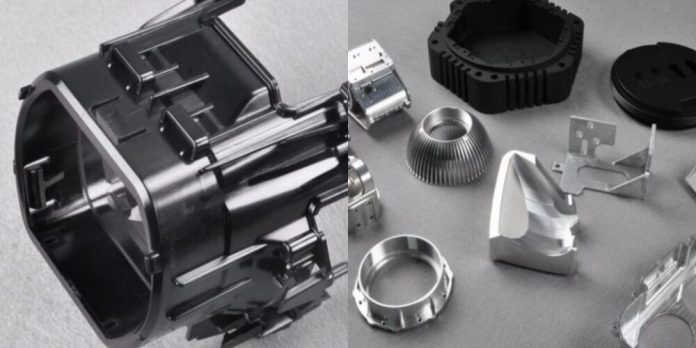

Companies that need to manufacture complex parts at a low cost lack the necessary manufacturing infrastructure. It leaves many businesses and individuals in a difficult situation; they can either continue searching for manufacturers or miss out on their opportunity to grow.

With CNC precision machining service, companies can reduce their overhead costs without the need for expensive production equipment or management overhead. All that’s required is a CAD file.

It’ll take care of all the preparations, machining, and finishing steps necessary before delivering your finished product. CNC precision machining services are a way for manufacturers of all sizes to add value to their products.

Manufacturers can control their supply chain, provide a wider range, and enhance brand identity and customer loyalty with custom precision machined parts. It also includes reducing lead times, improving turnaround time on production orders, and eliminating rework using pre-built parts.

Advantages Of CNC Precision Machining Services

It has been made to fit the exact specifications of customer orders without having additional tooling costs or prototyping expenses. Some significant benefits of CNC precision machining services are as follows:

· Reduce Material Waste

CNC precision machining services are a subtractive manufacturing process which means they create parts out of raw material by cutting away excess material. It can be an efficient way to machine products when the design is simple.

It reduces the amount of scrap that would generally occur with other manufacturing processes, like milling. You make components out of aluminum, stainless steel, and other materials, saving time and money.

· Enhance Workflow

Many operations are going once and for the same goal of working together to maximize efficiency. It makes sure you stay organized during your manufacturing process.

Whether it’s a single operation or multiple ones creating a complex part, CNC precision machining services can help workflow procedures. It is designed to enhance the overall performance of your production line.

· Less Turnaround Time

CNC precision machining services can help you save precious time in your production schedule. Cutting, milling, and grinding specifications can be provided through various materials, including titanium, hardened steels, and high-temperature alloys.

It offers complete service machining, including CNC turning, boring, and tapping on fully programmable. CNC machines can produce high tolerance and quick turnaround to close tolerances with the tightest surface finishes possible.

· Convenient Prototype Testing

Convenient prototype testing is a perfect way to check the product design and confirm the feasibility of your idea. Creating a precise physical model allows you to test and evaluate your design in the miniature form before committing to full-scale production.

It is a solution that reduces test time, eliminates expensive rework, and assures the highest quality of your end product. It provides an ideal path for production tooling and cost savings.

· Eliminates The Risk Of Errors

It provides a series of checks and balances to ensure that the machining process goes smoothly. It helps customer machines know their cutting data, including the cut location, time duration, etc.

This system prevents potential costly mistakes by spotting and eliminating errors before they are machine-generated, providing you with increased efficiency and more consistency.